Abstract

At present, most BMS in the market have set a constant fault threshold, but with the increase of power battery recycling times, the external characteristics of the battery will also change. After the battery aging diagnosis is not timely, a constant fault diagnosis threshold may also occur. Battery voltage is the direct embodiment of the external characteristics of battery, so the fault diagnosis of battery voltage is the most important. High or low battery voltage is the most obvious fault. Normally, this should not happen. Of course, due to the gradual aging of the battery pack, the inconsistency between the charging states of the single battery and each battery cannot be avoided. However, in the case of aging degree, the voltage difference caused by battery manufacturing or inconsistency is limited< span style="color: rgb(141, 179, 226);"> Based on the battery discharge data, the purpose of this study is to propose a method to identify the progressive fault signal in advance by detecting and diagnosing the problems caused by the sudden battery failure.

Summary

With the support of a series of national energy storage policies, the development of China's energy storage industry has entered a fast lane since 2018. In particular, the release of the "531 New Deal" has made the photovoltaic industry decline overnight. Enterprises and experts pushed the combination of photovoltaic and energy storage to the outbreak window. However, behind the hot development, due to the quality problems of batteries and PCs or the mixed construction capacity of system integrators, the potential fire risk also follows, and fire accidents often occur in energy storage power stations. In recent years, a large number of batteries in grid side energy storage power stations have been replaced by smoke batteries. The most serious problem was the burning and burning of the lithium iron phosphate battery container in the Zhenjiang user side energy storage project in early August. The accident immediately aroused widespread concern in the industry. The safety of lithium batteries that affect the whole industry has once again embarked on the cutting-edge road of the rapid development of the energy storage industry.

research status

The detection of lithium-ion battery is directly obtained by the voltage. The voltage and current of the battery are proportional to the current. Therefore, the charging state of the battery can be known by directly observing the voltage and current. With the development of lithium battery, the earliest SOC detection algorithm - ampere method, and then open circuit voltage method, load voltage method, internal resistance method and so on. These methods have relatively large errors. Later, the relatively mature mathematical methods model method and Kalman filter method have been well applied. After the emergence of neural network, intelligent control is applied to the on-line detection of battery. A series of algorithms in intelligent control field, such as artificial neural network method and fuzzy control reasoning method, have been well applied in on-line detection through improvement. Although the current lithium battery online detection technology has undergone qualitative changes compared with this century, it has realized the real-time online detection of battery SOC and SOH. However, the current research and industrialization practice is only the beginning. At present, there is no academic or industry recognized standard for battery SOC and SOH evaluation and their errors. More importantly, there is still a lack of a preventive diagnosis implementation scheme for battery thermal runaway and internal short circuit.

Battery failure mechanism

It should be noted that the internal short circuit caused by overcharge does not necessarily cause immediate heating out of control. The temperature rise of this process may not be sufficient to reach the thermal critical threshold. After the vehicle leaves the charging station, the battery temperature continues to rise, and the uncontrolled temperature causes the vehicle to catch fire. The internal short circuit caused by mechanical damage is caused by the extrusion / perforation of the battery during the vehicle collision. This situation is difficult to predict and can only be reduced through appropriate countermeasures.

At present, the fault mechanism of battery overcharge has been studied. When the battery is over charged, since the storage grid of the negative electrode is full, subsequent lithium ions will gather on the surface of the negative electrode material to form metal lithium ions.

The main manifestation of battery over discharge is the destruction of active material structure, which will cause permanent damage to the positive and negative electrodes of lithium battery. The continuous over discharge process will cause the negative potential of the battery to increase continuously. When the negative potential reaches the copper foil collector dissolution potential, the electrochemical reaction of copper foil dissolution will occur. The dissolved copper ions reach the positive pole of the battery through the diaphragm and are reduced to metallic copper in the low potential region. The gradually deposited copper grows in the positive direction and eventually passes through the diaphragm, causing an internal short circuit in the battery.

However, a large number of fault early warning and phenomena mainly focus on the research of electrochemistry. For lithium batteries in operation, it is difficult to avoid safety risks through existing fault research methods. Lithium battery can only collect voltage, current, temperature and other data< span style="color: rgb(141, 179, 226);"> How to directly characterize the fault characteristics of the battery through these external characteristic parameters is the focus of this paper.

Fault identification steps

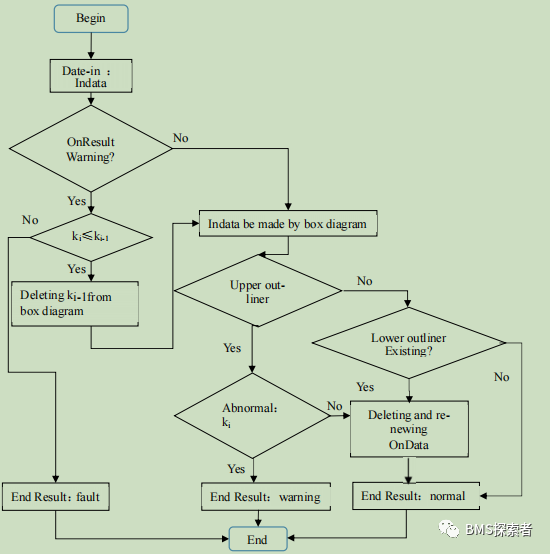

Based on the battery discharge data, theA method to detect and diagnose the change trend of extreme value difference of historical operation data, identify the progressive fault signal in advance, and reduce the problems caused by sudden battery failure . Delete the lower contour of abnormal value, obtain new input data, and output the final diagnosis result (normal). Step 1: process the real-time discharge curves of all single batteries in the target lithium-ion battery, extract the voltage values of SOC values of all single batteries, and record the voltage range. When the number of voltage range sets is greater than 2, the change rate of voltage extreme difference of I discharge curve is Ki, and the specific steps are to input data; The recorded data sets are as follows: record the data that meet certain SOC ± x% conditions during battery pack discharge; △ vi=vimax Vimin polarity difference calculation formula kii> 2ki= △ vi- △ vi-1 calculate the change rate of extreme value difference, where △ VI is the voltage difference under a SOC of I discharge curve, V is the minimum voltage discharge curve of Vimin for I when the maximum voltage Vimax is at a SOC of I discharge curve.

The value range of X is 0.5 ≤ x ≤ 1.

The block diagram of step 4 determines whether the internal data has an upper limit. Step 5; If the upper limit does not exist, determine whether the lower limit exists. Step 6: if it does not exist, output the final diagnosis (normal). After inputting the internal data set, use the block diagram to determine the abnormal value. The upper limit is calculated by the formula upper limit ≥ q3+1.5iqr, and the lower limit is calculated by the lower outline ≤ q1-1. 5iqr formula, where iqr=q3-q1, Q3 is the upper quartile, that is, the data set from small to large, the first quartile, the third (n+1) /4, Q1 is the next quartile, that is, the data set from small to large, and the quartile is the number (n+1) /4.

The target lithium ion battery includes lithium iron phosphate battery and ternary material battery. The battery pack can be a battery pack system with multiple cells connected in parallel and in series. This data includes the voltage value of SOC value when all individual batteries are discharged. SOC value can be 0-100% of any SOC value.

experimental verification

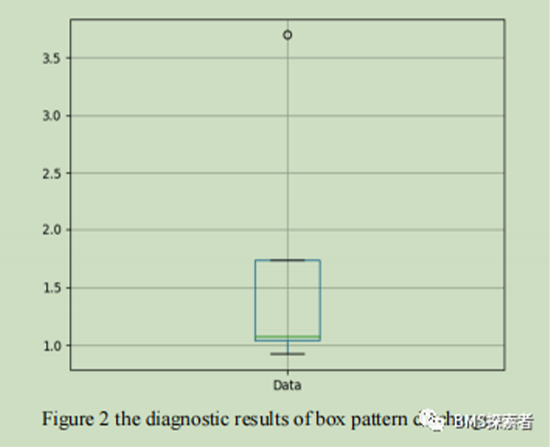

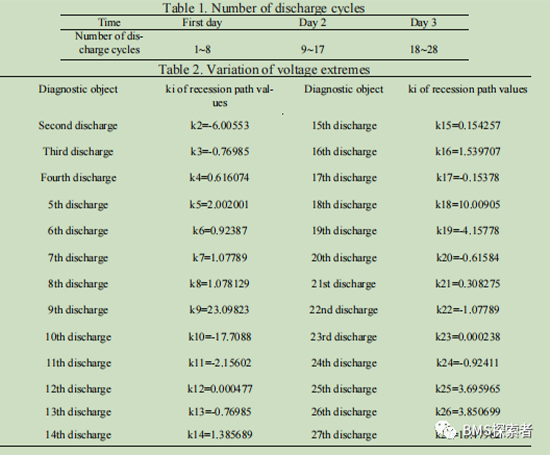

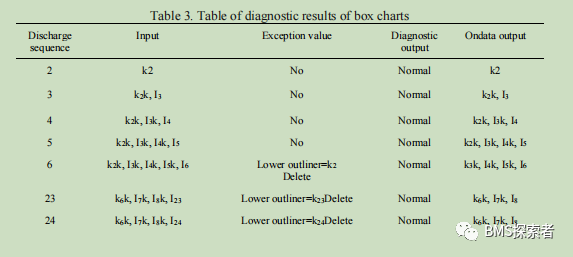

The constant current charge and discharge cycle shall be carried out under the constant temperature condition of 300A until the battery pack can not work normally. The experimental results were shared for 3 days. The battery pack was scrapped and the battery was in a constant temperature state. Extract the extreme value difference of the battery pack voltage under the 50%soc device from the previously discharged unit voltage data, and obtain the voltage range data set ∆ V ହ %={∆ V ଵ, ∆ V ଶ,.... ∆ V ୬}, where n is the number of cycles. The change of extreme value difference of battery pack discharge voltage with the number of cycles is shown in Figure 2, and the specific time corresponding to the number of discharge cycles is shown in Table 1. In general, before the battery pack is completely scrapped, the voltage extreme value difference increases orderly, except for the partial maximum value at No. 9 discharge and the 18th discharge, which are affected by external temperature factors; From 25 discharges to 28 discharge cycles, the change rate of pole voltage difference increases, especially in the 27th and 28th discharge, the difference between the extreme voltage difference and the data set is large and rises sharply. Table 3 shows the partial detection input and output data of the battery pack from the beginning to the detected fault. The 25th discharge before the fault occurs is an early warning.

Up to 26 times of discharge, and the test result is failure, indicating that the battery pack has progressive failure and needs to be repaired or replaced. In the test results of cycle aging, the battery pack had 28 discharge cycles before complete failure (unable to charge and discharge normally). The block diagram based progressive fault detection method used in this paper can identify fault information in advance. This method avoids the safety and economic impact of sudden failure on the project / system.

Generally, the voltage extreme value difference will increase orderly before the battery pack is completely scrapped. Under normal conditions, the change rate of voltage extreme value difference changes steadily. Therefore, it is feasible to predict battery failure by monitoring the change rate of battery voltage difference.

Home

Home Products

Products Telephone

Telephone Message

Message